What are you looking for?

- Samsung Community

- :

- Products

- :

- Home Appliances

- :

- Re: wf70f5e3p4w - remove motor

wf70f5e3p4w - remove motor

- Subscribe to RSS Feed

- Mark topic as new

- Mark topic as read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page

16-11-2019 05:50 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

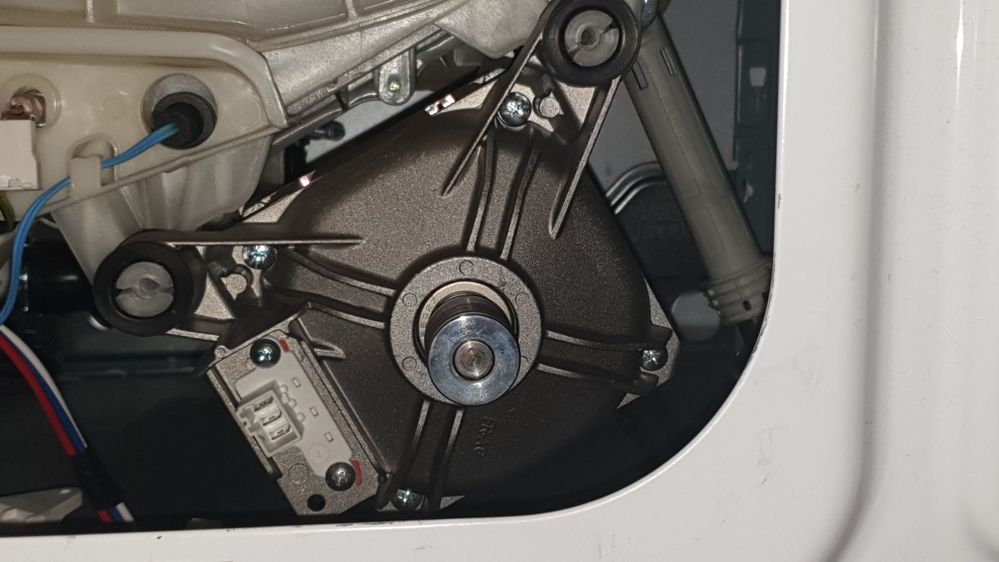

As everyone here my washer stops midway and lately giving 3e warning and research shows I need to check the carbon. But I can not for the love of God remove the motor. What do I need to do? I removed 2 bolts.

17-11-2019 12:42 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

http://www.samsung.com/uk/support/servicelocation/

15-01-2020 09:59 AM - last edited 19-01-2020 11:40 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Samsung WF1124XAC

Samsung also recommended I replace my washing machine directly and save 25% on a replacement (!)

Following yet another 3E error last week, I managed to locate a new main PCB for my 12 kg model from 2014. That needed replacing a WEEK before the warranty expired in Feb 2016. Well, it's given me four years of service until last week (Jan 2020) where the error has come back. Replacing it really did the trick.

At £146 it's not cheap to buy, but it's better than that plus a callout and technicians fee, which could mount to £200 more.

Sorry, Samsung, I get the BEST wash from your Ecobubble, but if it goes again, I'll either replace the PCB AGAIN or buy an LG.

My mum's Bendix Deluxe lasted 10 years from 1979, and then her Zanussi lasted 18 years. No one should go through four washing machines in a decade!

30-12-2022 12:27 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

A bit late sorry but I'm new to the game. For anyone else finding this issue, I have repaired our WF Ecobubble with decent success.

First off a year or so ago we had the 3E error intermittently then consistently. I replaced various components from having continuity tested including pressure switch, solenoid etc. Problem prevailed. Then just as I was about to give up and started to fully tear it down for parts, I found a blown (burned out) wire connection in the harness going into the motor. It had totally blown itself out of the harness itself. I don't recommend this and take no responsibility if anyone does it but I cut the wire and bypassed the harness, it took away the error message. However I when I was fiddling around with the harness I noticed the mounting bushes were seriously perished, almost non existent. I figured this probably caused the wire blowing that went into the harness due to excessive vibrations. I also imagine this could be causing people's PCB to defect if the wire is intermittently arcing as it comes loose then eventually blows completely. So I went ahead and replaced all the bushes (espares site says they aren't compatible but they were a perfect fit strangely, I'm guessing they just haven't added my specific model to their database or something). I also put in some new shock absorbers for good measure while it was all apart. It ran like brand new, for a while.

Fast forward a few months and it was vibrating like crazy again on spin so I opened it up to find the new bushes were shot again. I took them off and gave it all a proper inspection. I figured out that the rear most posts coming off the main drum housing which the rubber motor bushes mount onto were really warped out of shape causing areas which would prematurely wear any new bushes. NO way I was going to replace that as it would mean a complete tear down and rebuild. Not worth the bother so I came up with an alternative. I found that 20mm mdpe blue water pipe fits exactly in the holes on the motor mounting points. The inner diameter may have been a perfect fit for the posts but since they were so warped and worn down there was some play. I happened to also have some ugh 16mm twin skinned polypipe (am sure 15mm regular polypipe would do) so I used this to cut sections out to make up the profile into a more rounded and not oblong shape. Padded it all out a bit with friction tape although I would have thought any strong tape would suffice (not duck tape as too lumpy or electricians tape as it would disintegrate). The 20mm made slid nicely over with a bit of wiggling and has resulted in a secure and more robust solution than the rubber bushes which would likely perish again in no time.

In my opinion this is a case of planned obsolescence by Samsung. Not exclusively guilty of this of course but annoying really as we got 8 yrs of trouble free great use out of it before this. As noted, even a Hotpoint in times gone by would have lasted 20+ yrs no sweat.

Anyway, hope this helps someone out there. Again I do not recommend doing what I did or anything like it and a word of caution to only work on electrical parts if you are a competent person. Switch everything off and try not to flood your house!